Costomized Casting Gehäuse Teile Formenhersteller in Dongguan

Basisinformation

Modell: kenos--2013

Produktbeschreibung

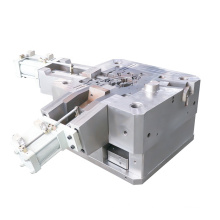

| Product name | Costomized die casting housing parts maker in Dongguan | |||||

| Briefly Description | 1. magnesium or zinc alloy are the main product material | |||||

| 2.10 year's experience in die casting field | ||||||

| 3.OEM and ODM service offered | ||||||

| 4. One stop service from die cast mould making to product casting | ||||||

| Mold type | Die casting mould | Usually packaging | Paper of Box | |||

| Manufacturer | Kenos Hardware Technology | Orginal place | Dongguan China | |||

| Supply capability | 50000PCS/WEEK | Terms of transport | by ship or express | |||

| About Our Mould : | ||||||

| 1)Mold type: die casting mold as customer's drawing or sample | ||||||

| 2)Mold tolerance:generally wirthin +/-0.03mm | ||||||

| 3)Mold size:either small or big are available according to product,generally length from 100mm to 1 meter | ||||||

| 4)Mold making process:milling,grinding,wire cutting,CNC,EDM,etc | ||||||

| 5)Mold making equipment: | ||||||

| 1. eight sets of milling machine | ||||||

| 2.three sets of grinder | ||||||

| 3. two sets of wire cutting machine | ||||||

| 4. one set of CNC machine | ||||||

| 5. five sets of EDM machine | ||||||

| 6)Mould life:Over 1000,000 shots,lifetime free for maintaining the mould | ||||||

| 7)Drawing type:PDF,DWG,IGS,STP,STEP,PRT are all acceptable | ||||||

| About Our Product: | ||||||

| 1)material type:mainly magnesium and zinc alloy with SGS certification | ||||||

| 2)Product tolerance:according to customer's requirement and decided by the mold | ||||||

| 3)Main products:die casting parts,die casting accessories,die casting components, including phone shell,automotive parts,compouter parts,PC parts,bicycle parts,camera parts,housing,parts,gears,diy tools,optical components,engine components,pump components,furniture,fittings,etc | ||||||

| 4)Related industry:computer,cellphone,communication,LED,automotive,Camera,optical,etc | ||||||

| 5)Main process: Die casting,deburring,hole drilling,tapping,polishing,plating,inspecting,packaging | ||||||

| 6)Product making equipment: | ||||||

| 1. 3 sets of magnesium alloy die casting machine (hot chamber) | ||||||

| 2. 4 sets of zinc alloy die casting machine | ||||||

| 3. 4 sets of aluminum alloy die casting machine | ||||||

| 4. 34 sets of punch press | ||||||

| 5. 4 sets of hole-punching machine | ||||||

| 6. 15 sets of tapping machine | ||||||

| 7. 2 sets of CNC machine | ||||||

| 8. 10 sets of lasering welding machine | ||||||

| 7)surface finish:Zinc plating,Chrome plating,Trivalent chrome plating,Powder coating,Painting,E-Coating.Phosphating,Anodizing,etc | ||||||

| Our main advantage: | ||||||

| 1)specialize in magnesium and zinc die casting for 10 years | ||||||

| 2)Green products with many international certification | ||||||

| 3)Good quality products with competitive price | ||||||

| 4)Best after-sale service | ||||||

| 5)One stop service to solve all of your problems | ||||||

| 6)Always on service for you during your working time | ||||||

| 7)Quotation will be sent within 24 hours any time | ||||||

| 8)Always on service for you during your working time | ||||||

| 9)Samples could be provided for customer's trail and test.Once not meet customer's need, | ||||||

| we will modisfy the mold until customer's satisfactory | ||||||

Mould Design

Fräsen Processing

EDM wire Cutting

Form Inspection

Form InspectionProdukt sterben Casting-Prozess:

Magnesium sterben Casting

Degating

Deburring

Bohr- und Tapping

Produkt Inspektion:

Messraum 1

Inspektion Raum 2

Paket :

Produktgruppe : Druckgussform

Premium Related Products

andere Produkte

heiße Produkte

Edelstahl-Feinguss-Gehäuse-BoxZinkgehäuseBiegen von WohnungenSphäroguss Teile-Grüne Sand CastingFilter Cap-CNC Bearbeitung von Casting Ss316, WachsausschmelzverfahrenAuto Lock Body-Edelstahl Ss316 WachsausschmelzverfahrenSS-Feinguss (AISI304)Schmieden von Teilen für die EisenbahnschwenkfrontDuktiles Gusseisen der Nabe aus verlorenem SchaumgussRohrfittings Aluminium Gravity CastingEspresso Kaffeemaschine Gehäuse von Druckguss mit ausgezeichneten FinishHerstellung von hochpräzisen Zamak Druckguss Samsung HandytascheHochdruck-Aluminium Druckguss Kommunikationskomponentennach Maß aus Aluminium, Zink und Magnesium-Druckguss LegierungPräzisions kultiviere Druckguss Handy GehäusePräzisions Magnesium Gussform Formenbau